mercury dts controls manual

This manual provides essential guidance for the installation‚ operation‚ and maintenance of Mercury DTS (Digital Throttle and Shift) systems. Designed for authorized personnel‚ it ensures proper setup and optimization of controls‚ enhancing boating performance and safety. The DTS system offers smooth shifting and instant throttle response‚ making it a cutting-edge solution for marine propulsion control.

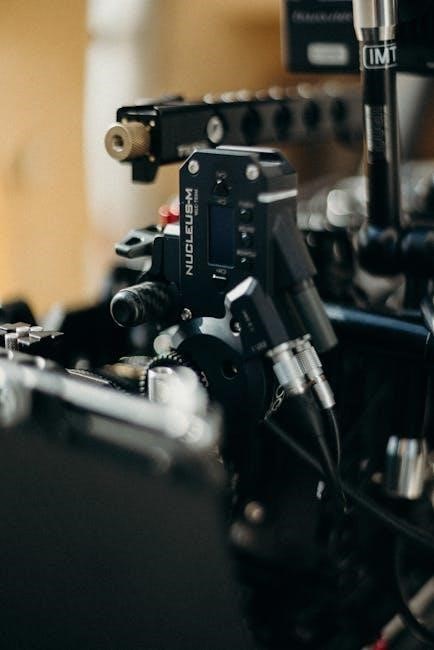

Overview of Mercury DTS Systems

Mercury DTS (Digital Throttle and Shift) systems represent a cutting-edge advancement in marine propulsion control. These systems integrate digital technology to provide smooth shifting and instant throttle response‚ eliminating hesitation and enhancing overall performance. Designed for compatibility with both single and multi-engine setups‚ DTS systems are customizable to meet specific boating needs. They also feature Active Trim integration‚ allowing for real-time adjustments to optimize speed and efficiency. With ergonomic controls and an intuitive interface‚ Mercury DTS systems deliver a seamless and enjoyable boating experience‚ combining innovation and reliability for superior control.

Importance of Proper Installation and Calibration

Proper installation and calibration of Mercury DTS systems are critical to ensure optimal performance‚ safety‚ and reliability. Incorrect setup can lead to system malfunctions‚ reduced efficiency‚ or even safety hazards. Only authorized‚ trained technicians should perform these tasks‚ as they require specialized knowledge and tools. Calibration ensures precise throttle and shift responses‚ while incorrect settings may result in poor engine performance or damage. Adhering to the guidelines outlined in this manual is essential to maximize the benefits of the DTS system and maintain the overall integrity of your marine propulsion system.

Features and Benefits of DTS Controls

Mercury DTS controls offer smooth shifting‚ instant throttle response‚ and seamless integration with Active Trim for enhanced performance. Their ergonomic design and intuitive interface provide a premium boating experience.

Smooth Shifting and Instant Throttle Response

The Mercury DTS system delivers seamless shifting and instantaneous throttle response‚ ensuring precise control and a responsive boating experience. By eliminating mechanical delays‚ it allows for smooth acceleration and effortless gear transitions‚ enhancing overall performance. This advanced technology minimizes hesitation‚ providing immediate power delivery when needed‚ making it ideal for both casual cruising and high-performance applications. The system’s digital precision ensures consistent and reliable operation‚ contributing to a more enjoyable and efficient time on the water.

Active Trim Integration for Enhanced Performance

The Mercury DTS system seamlessly integrates Active Trim‚ enabling real-time adjustments for optimal boat performance. This feature‚ accessible directly from the DTS control‚ allows for dynamic trimming to enhance speed‚ fuel efficiency‚ and handling. By automatically or manually fine-tuning the trim‚ the system ensures the boat operates at its best under varying conditions. This integration simplifies operation‚ providing improved responsiveness and a smoother ride‚ while also reducing operator fatigue. The Active Trim system is a key component of the DTS controls‚ elevating the overall boating experience.

Ergonomic Design and Intuitive User Interface

The Mercury DTS controls feature an ergonomic design that prioritizes comfort and ease of use. The intuitive interface ensures seamless operation‚ with controls logically arranged to minimize operator fatigue. Buttons for functions like Active Trim are conveniently located‚ providing instant access to performance-enhancing features. The design caters to both single- and multi-engine setups‚ offering a user-friendly experience that enhances overall boat control. This combination of comfort and functionality makes the DTS system a premium choice for boaters seeking precision and ease of operation.

Installation Requirements and Guidelines

Installation requires a trained installer certified in Mercury DTS systems. Ensure electronic calibration is performed correctly‚ and verify compatibility with electric steering systems. Improper installation can lead to unsafe operation.

Trained Installer Requirements for DTS Systems

Installation of Mercury DTS systems requires a certified installer trained by Mercury Marine. Proper training ensures understanding of electronic calibration and system operation; Installers must follow detailed guidelines to avoid malfunctions. Incorrect installation can lead to unsafe conditions or system failure. Only authorized personnel should perform DTS system setup and adjustments. Training is available at Mercury Marine service centers‚ emphasizing safety and performance optimization. Always refer to the official manual for specific certification requirements and procedures.

Electronic Calibration Process

The electronic calibration process for Mercury DTS systems must be performed by a trained installer using specialized diagnostic tools. Connect the diagnostic tool to the engine’s ECU to synchronize system data. Follow the on-screen instructions for throttle and shift adjustments. Ensure all components‚ including sensors and actuators‚ are properly aligned. After calibration‚ test the system to confirm smooth operation. Improper calibration can lead to performance issues or safety risks. Always refer to the official manual for detailed calibration procedures and safety guidelines.

Compatibility with Electric Steering Systems

Mercury DTS systems are fully compatible with electric steering systems‚ ensuring seamless integration and enhanced performance. The DTS control units‚ such as the ERC-892984A01 and ERC-883465A1‚ are designed to work harmoniously with electric steering‚ providing precise control and responsiveness. This compatibility allows for smooth operation in both single-engine and multi-engine configurations. Proper installation by a trained technician is essential to maintain optimal functionality and safety. Always refer to the official manual for specific compatibility requirements and installation guidelines.

Troubleshooting and Maintenance

Regular inspections and routine maintenance ensure optimal performance of Mercury DTS controls. Address any system errors promptly‚ as improper installation or calibration can lead to operational issues. Always refer to the official manual for detailed troubleshooting steps and maintenance schedules to maintain reliability and safety.

Basic Troubleshooting Steps for DTS Controls

Troubleshooting DTS controls begins with checking electrical connections and ensuring proper system calibration. Review error codes using Mercury diagnostic tools to identify issues. Verify throttle and shift lever alignment‚ and test response during operation. Inspect for worn or damaged components‚ such as sensors or wiring‚ and replace as needed. Refer to the manual for specific procedures and guidelines. Always ensure adjustments are made by a trained technician to avoid further complications and maintain system reliability.

Regular Maintenance Recommendations

Regular maintenance of Mercury DTS controls ensures optimal performance and longevity. Inspect electrical connections and wiring for damage or corrosion. Check for software updates and apply them as needed. Verify throttle and shift lever alignment to prevent misalignment issues. Lubricate moving parts according to Mercury’s guidelines. Refer to the owner’s manual for specific maintenance schedules and specifications. Routine checks help prevent complications and ensure reliable operation of the DTS system. Always follow recommended procedures to maintain the integrity and functionality of the controls.

Remote Control and System Calibration

The Mercury DTS system requires precise calibration using diagnostic tools to ensure smooth shifting and instant throttle response. Follow the manual’s guidelines for optimal performance.

Using Mercury Marine Diagnostic Tools

Mercury Marine diagnostic tools are essential for calibrating the DTS system. These tools detect the remote control and guide through the calibration process. Proper training is required to use these tools effectively. Calibration must be performed by authorized personnel to ensure system functionality and safety. The diagnostic tool helps troubleshoot issues and optimize performance. Refer to the manual for detailed instructions on connecting and operating the diagnostic system. Regular updates to the tool ensure compatibility with the latest DTS features. Always follow the manufacturer’s guidelines for accurate calibration and system maintenance.

Calibration Steps for Optimal Performance

The calibration process for Mercury DTS systems ensures precise throttle and shift control. Begin by setting the remote control to idle and adjusting the lever to the neutral position. Utilize Mercury’s diagnostic tool to initialize the system and synchronize all components. Follow the tool’s prompts to set idle speed and verify smooth transitions between gears. Calibration must be performed by a trained technician to avoid system malfunctions. After completing the process‚ test the system under various conditions to ensure optimal performance and responsiveness. Regular recalibration is recommended to maintain peak functionality and safety.

Advanced Features of DTS Controls

DTS controls offer advanced features like SmartCraft integration and digital gauges‚ providing real-time monitoring and enhanced performance. These features ensure a seamless and intuitive boating experience.

SmartCraft Control Systems Integration

SmartCraft integration with DTS controls enhances vessel performance by providing real-time data and advanced monitoring capabilities. This system seamlessly connects engine diagnostics‚ fuel efficiency‚ and vessel speed‚ offering precise control and optimization. With SmartCraft‚ users can access detailed information on engine performance‚ trim levels‚ and fuel consumption through digital gauges. This integration ensures a user-friendly interface‚ allowing for intuitive operation and improved overall boating efficiency. The combination of DTS and SmartCraft delivers a premium‚ connected experience for boat operators.

Digital Gauges and Monitoring Capabilities

Digital gauges in the Mercury DTS system provide real-time monitoring of engine performance‚ fuel flow‚ and trim levels. These gauges integrate seamlessly with SmartCraft‚ offering a comprehensive view of vessel operations. Users can track key metrics like RPM‚ speed‚ and fuel efficiency‚ enabling precise control and optimized performance. Customizable displays allow operators to prioritize essential data‚ enhancing situational awareness. This advanced monitoring capability ensures effortless control and improved efficiency‚ making it a vital feature for modern boating experiences;

Safety and Operational Guidelines

Adherence to safety protocols ensures reliable operation of Mercury DTS systems. Proper installation and usage‚ as outlined in the manual‚ prevent hazards and maintain optimal performance.

Idle Speed Adjustments

Proper idle speed adjustments are critical for optimal engine performance. Refer to the manual for specific idle speed specifications‚ as incorrect settings can lead to poor engine efficiency or damage. Adjustments should only be made by authorized personnel using Mercury-approved tools. Ensure the engine is warmed up before making any changes. Idle speed adjustments impact fuel efficiency‚ smooth operation‚ and overall system reliability. Always test adjustments under load conditions to confirm stability. Follow the manual’s guidelines to avoid potential safety hazards or system malfunctions.

Valve Clearance Specifications

Valve clearance specifications are critical for maintaining engine performance. Measurements must be taken under cold engine conditions‚ with specific clearances for intake and exhaust valves. Refer to the manual for exact specifications‚ as deviations can lead to poor efficiency or damage. Adjustments require specialized tools and should only be performed by trained technicians. Proper valve clearance ensures optimal combustion and reduces mechanical stress. Always follow the manual’s guidelines to maintain engine health and overall performance.

The Mercury DTS Controls Manual serves as a comprehensive guide for optimal system performance. By adhering to installation‚ calibration‚ and maintenance procedures‚ users can ensure safe and efficient operation. Proper use of diagnostic tools and adherence to specifications are vital for maximizing the benefits of DTS technology. Regular maintenance and trained professional assistance will extend system longevity and reliability. This manual underscores the importance of correct practices to enhance boating experiences while maintaining Mercury’s high standards of innovation and quality.